Industrial activities, from electricity generation to cement production, are responsible for emitting huge amounts of greenhouse gases, including carbon dioxide (CO2). Reducing the amount of greenhouse gases in the atmosphere is vital for Europe to become climate-neutral by 2050.

To this end, the EU-funded CarbFix2 project recently tested and upscaled groundbreaking carbon capture and storage (CCS) technology. This is a method that involves removing CO2 at the emission source, such as a factory chimney, then transporting and safely storing it.

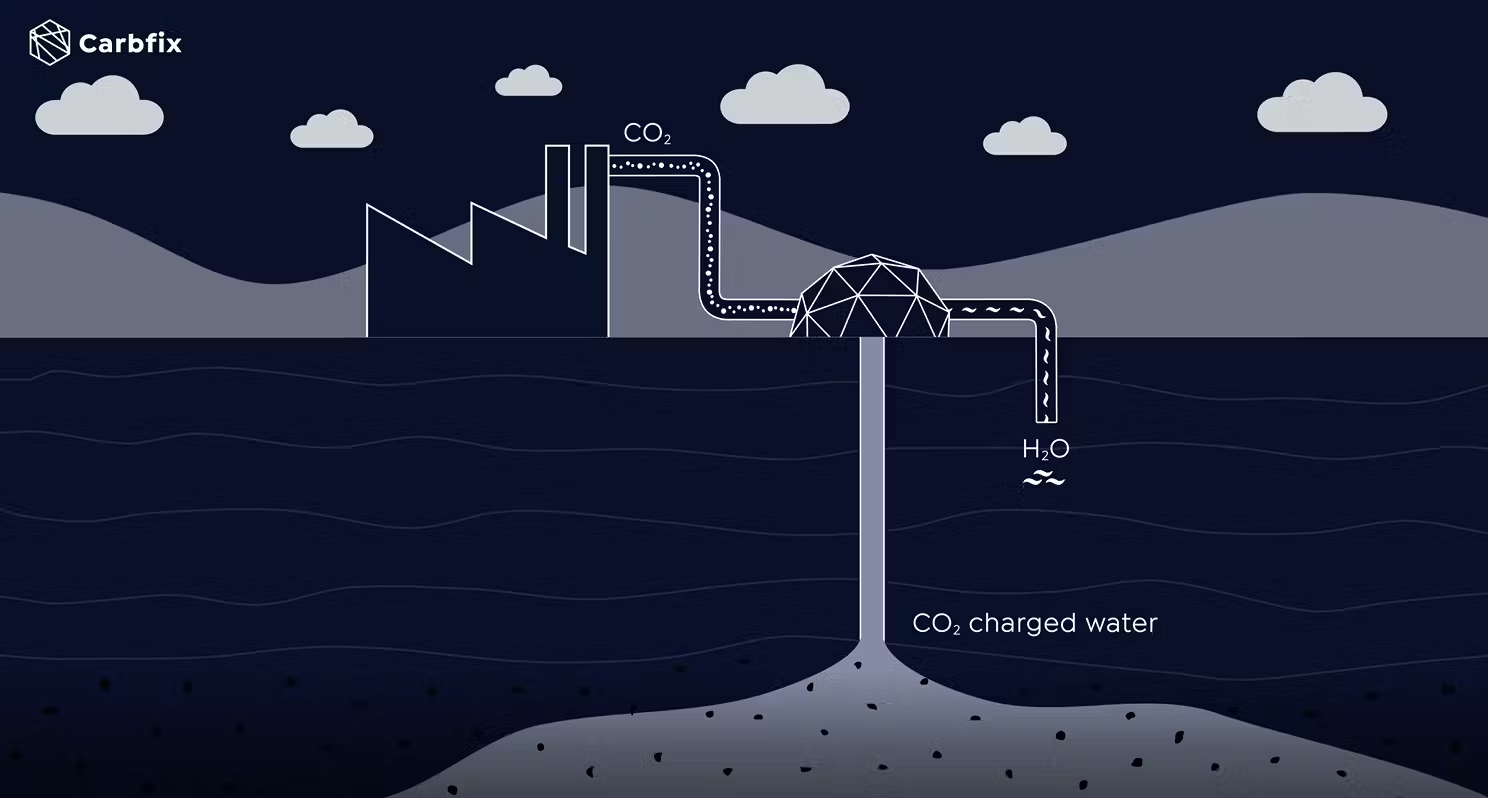

What makes CarbFix2’s innovation unique is that captured CO2 is dissolved in large volumes of water, and then permanently stored underground in the form of rock. The process is a little like adding CO2 to bottled water in order to make a fizzy drink – but on a much larger scale. Chemical reactions then solidify the dissolved CO2 into rock, preventing it from escaping into the atmosphere.

The project recently played host to American actor Zac Efron for ‘Down to Earth’, a Netflix travel show exploring healthy and sustainable ways to live, and has been featured on the BBC, HBO, National Geographic and more.

Extracting, dissolving and storing CO2

CarbFix2 sought to build upon the success of previous projects, and ensure that this technique could be scaled up to fully meet the needs of industry.

“Carbon capture and storage is a vital part of climate action,” explains CarbFix2 project coordinator Edda Sif Pind Aradóttir. “We wanted to optimise this method as an economically viable option for industry.”

The project was centred at the giant Hellisheiði Geothermal Power Plant in Iceland, one of the largest in the world. The plant harnesses volcanic heat to generate electricity and provide hot water for much of the country’s population. Continuous capture of CO2 emissions from the steam emitted by the plant has been ongoing since 2014.

Through CarbFix2, the work was scaled up. The team was able to identify best practices for dissolving gases emitted by the plant, in fresh water reservoirs. A comprehensive monitoring and verification programme was developed and put in place, to assure the safety of permanent storage underground.

“We also increased our knowledge about geochemical mineralisation processes,” says Aradóttir. “This provided the basis for carrying out full-scale tests of injecting gas into seawater.”

In addition, a direct air capture facility was built at the Hellisheiði Geothermal Power Plant, to extract CO2 directly from the atmosphere. The project team then linked up this extraction process with the dissolving and storage steps, in order to demonstrate the economic viability of the entire process.

Capturing CO2 from industrial emissions

The CarbFix2 project demonstrated on a larger scale than ever before that CO2 from industrial emissions can be safely captured and stored as rock below ground. “This mineralisation process usually takes place over thousands of years, if it happens at all,” adds Aradóttir. “With our technology, this is possible within a couple of years.”

Carbfix as a company was founded shortly after the project was completed, in order to bring the technology to market. As the world’s first CO2 mineral storage operator, the start-up has generated a lot of excitement. For example, Deputy Secretary-General of the United Nations, Amina J Mohammed, recently visited the company to discuss CO2 mineralisation and its immense potential around the globe.

The project continues to help reverse climate change and inform policies such as the EU Green Deal, which aims to make the EU climate-neutral by 2050. “We have already signed agreements on scaling up direct air capture and mineral CO2 storage,” notes Aradóttir. “The first project, which began in 2021, permanently removes 4 000 tonnes of CO2 from the air every year. Construction of a tenfold scale-up is currently ongoing.”

Preparations are also under way for the Coda Terminal. This terminal will be a cross-border carbon transport and storage hub in Iceland. CO2 captured at industrial sites in northern Europe will be shipped to the terminal and unloaded into onshore tanks for temporary storage.

The CO2 will then be pumped into a network of nearby injection wells, where it is dissolved in water before being injected into the ground. The terminal is expected to begin operations in 2025.