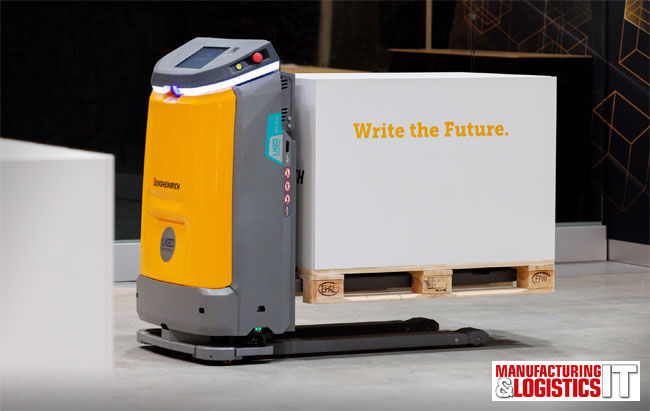

Jungheinrich has premiered its latest mobile robot solution at Stuttgart’s LogiMAT 2023, the international trade fair for intralogistics solutions.

It is a robot that can be easily integrated into any warehouse, which finds its own solutions, and which adapts to changing warehouse needs, increasing performance and efficiency.

Jungheinrich’s EAE 212a is a next generation Autonomous Mobile Robot (AMR). Its newly developed control system and toolchain enable smooth, simple integration with any existing warehouse environment and guarantee impressive flexibility from planning stage to day-to-day operations. “The simple integration, maximum flexibility and scalability of the EAE 212a are truly impressive,” says Spencer Goss, Director of Projects with Jungheinrich UK. “This really is the future of intralogistics.”

Next generation AMR

The EAE 212a is designed for the automation of low-level applications. Thanks to its Jungheinrich-patented chassis design, its width of just 790mm is even narrower than a Euro pallet, and offers impressive manoeuvrability and agile floor-to-floor transports at speeds of up to 6 km/h. At the same time, the vehicle can move loads of up to 1.2t safely and stably. “As a low-level vehicle, the EAE 212a complements our existing mobile robot portfolio and is perfectly suited for the supply and disposal of incoming and outgoing goods lanes,” says Spencer.

Easy integration into existing warehouses

The EAE 212a navigates entirely without any artificial landmarks, rendering time-consuming preparatory warehouse measures a thing of the past.

Particular emphasis on the interaction between hardware and software enables complete integration with the warehouse system.

The proprietary Jungheinrich Mobile Robot Control (MRC) includes central order management, truck control, a modelling tool and real-time visualization. Thanks to the new modelling tool, project planning with the EAE 212a is possible within a few hours. Simple projects can be planned in as little 30 minutes.

Scalability for the future

The new toolchain, an integral part of the new mobile robot, enables it to quickly adapt travel routes and areas to changing warehouse needs. Designed for maximum scalability, additional EAE 212a AMRs can be easily added to warehouses when projects need expanding at short notice.

The EAE 212a can be used as a standalone solution or connected to the warehouse’s existing host system. Thanks to control system compatibility based on the VDA-5050 standard and a future-proof software platform, the mobile robot solution is geared to handle any future challenges in the warehouse environment.

Finding its own solutions

Thanks to its high degree of autonomy, the EAE 212a finds its own solutions during operation, avoiding obstacles and continuing its work without human intervention. Target recognition enables the EAE 212a to detect pallets that are not exactly in their desired position. This makes it possible to integrate the system into manual processes, even in a cluttered warehouse.

Human-machine interaction

Underpinning the development of the EAE 212a was a focus on simple, intuitive communication between machine and human. With immediate and unambiguous information at the control station, LED strips for clear visibility at a distance or the display at close range, EAE 212a’s human colleagues have all the information they need to work safely and productively together. This helps the mobile robot solution to achieve a high level of acceptance among employees.

“We’ve poured all our extensive material handling equipment know-how and process and software expertise into EAE 212a,” says Spencer. “The result is thecomprehensive flexible floor-to-floor transportation solution for warehouses.”

The EAE 212a will be available in the UK in 2025.