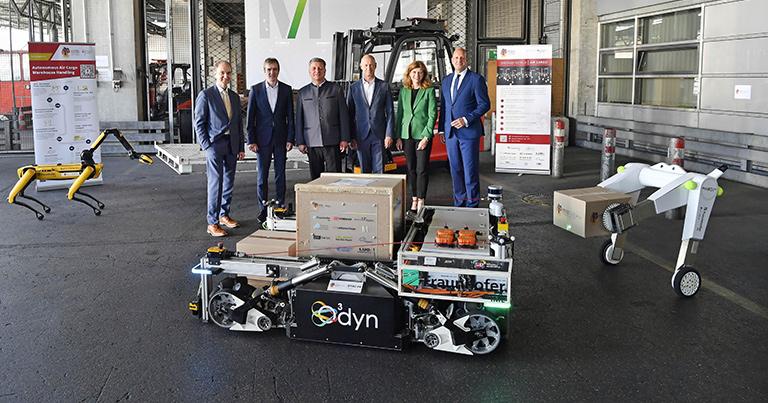

Researchers from Fraunhofer IML (a Corporate Partner of the FTE Digital, Innovation & Startup Hub and a Partner of the FTE Baggage Innovation Working Group) have demonstrated the initial results of the ‘Digital Testbed Air Cargo’ (DTAC) research project at Munich Airport. The groundbreaking solutions are designed to make optimal use of the potential of digital technologies and actively shape the future of air cargo.

A ‘robot dog’ patrolling autonomously through the warehouse looking for free storage locations, a highly dynamic transport robot that automatically moves pallets to their storage locations, and a very flexible ‘segway robot’ that places parcels from Euro-pallets onto a conveyor belt, were among the solutions demonstrated.

Artificial Intelligence (AI), Robotics, and the Internet of Things (IoT) are the three key themes of the FTE Digital, Innovation & Startup Hub in 2024.

“The cooperation between Fraunhofer IML and Munich Airport is future-oriented,” said Dr Jan-Henrik Andersson, Chief Commercial Officer & Chief Security Officer, Munich Airport. “Considering the increasing volume of air cargo and the staff recruitment challenges, digitalisation and robotics will help us make cargo and baggage handling more efficient and jobs in these areas more attractive in the near future.”

The DTAC project, which is funded by the German Federal Ministry for Digital and Transport with around €7 million and will run until September 2024, is focusing on how the efficiency and performance of the air freight transport chain can be optimised. This is to be achieved through better networking and digitalisation of processes. During the demonstration of the project in Munich, several autonomous and automated devices were successfully used to either completely take over some very labour-intensive and repetitive steps at relevant interfaces in the handling process, or to support employees in their physically demanding work.

“On the hardware side, as today has clearly shown, we are already well advanced,” said Prof Michael Henke, Executive Director, Fraunhofer IML. “In the future, Artificial Intelligence will support us in coordinating and controlling the vehicles. It will provide the necessary tools and algorithms with which we can pre-calculate the routes of the autonomous robots and safely avoid collisions. Ultimately, we will soon have fully autonomous systems that will make the air cargo industry fit for the future.”

Hear more from Munich Airport at the co-located FTE EMEA and FTE Ancillary & Retailing events, taking place in Dublin on 11-13 June 2024. Swapnal Chouhan, Head of Competence (Airport Management & Commercial), Munich Airport, is speaking in The AI Travel Retailing Symposium, which will focus on how we can leverage AI for dynamic offers, disruption management, customer engagement, trip planning and much more.

View the FTE EMEA and FTE Ancillary & Retailing schedule at a glance >>

Register for FTE EMEA and FTE Ancillary & Retailing – one registration provides access to both events >>