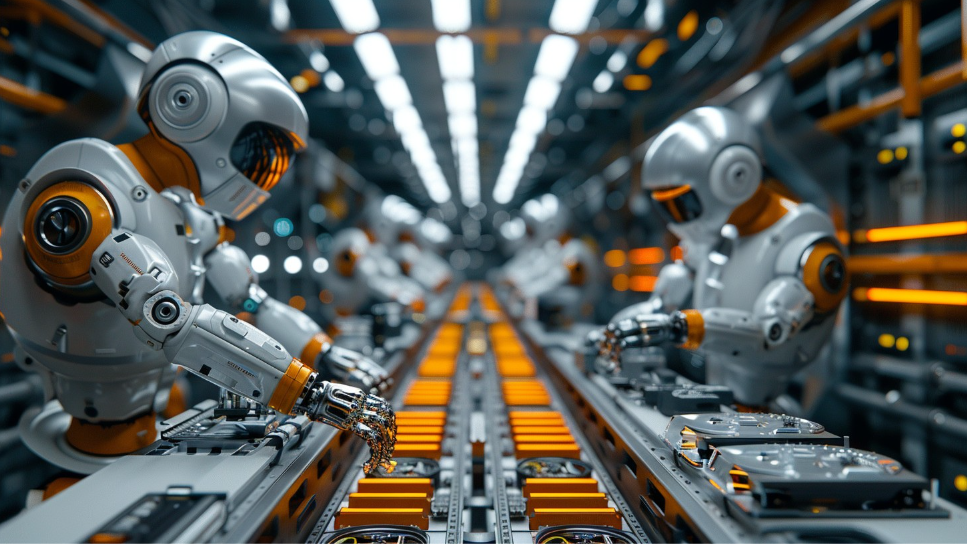

The concept of “dark factories”—automated facilities that require little or no human intervention—has rapidly gained attention in the manufacturing world, fueled by advancements in robotics, AI, and the Industrial Internet of Things (IIoT). While these systems promise to revolutionize production by driving efficiency, sustainability, and safety, the full implications of a shift toward fully automated factories remain complex and fraught with challenges. This article explores both the promises and pitfalls of dark factories, and how companies can proceed carefully into this new industrial landscape.

The Promise of Dark Factories

Dark factories operate without the need for human labor, driven by robots, AI, and advanced connectivity. Their benefits are immediately apparent:

- Increased Efficiency & Productivity: Dark factories can operate around the clock, unaffected by human constraints like breaks, holidays, or sick days. This continuous operation leads to higher output and reduced downtime.

- Cost Efficiency: By eliminating the need for lighting, heating, and large workforces, dark factories significantly lower operating costs. Additionally, companies are no longer tied to labor pools, allowing them to set up facilities in cheaper locations.

- Sustainability: With automation comes a greater ability to optimize energy use, leading to more environmentally friendly operations. Less energy is wasted, and fewer resources are consumed, especially when compared to traditional factories.

- Improved Safety & Quality: Fewer workers on-site reduce the risk of accidents. Specialized machinery and AI-powered systems can also ensure higher product quality and consistent performance, while also reducing human error.

The Dark Side: Risks and Challenges

While the potential benefits of dark factories are clear, the reality of implementing and maintaining them is more complicated:

- High Capital Expenditure (CAPEX): The upfront cost of transforming a traditional factory into a dark one is significant. Companies must invest in new infrastructure, advanced robotics, AI, and seamless system integration, often requiring substantial investment in both time and resources.

- Technological Barriers: Successfully implementing dark factories involves overcoming several technological challenges, from integrating AI and machine learning into systems, to the complexity of ensuring reliable 5G connectivity for real-time operations.

- Job Displacement & Skills Gap: As automation takes over, the workforce may shrink, creating a demand for new skills that workers are not necessarily prepared for. It’s crucial for companies to address workforce retraining, or face the societal implications of significant job losses.

- Cybersecurity Risks: Increased connectivity comes with a heightened risk of cyberattacks. Malicious actors could exploit vulnerabilities, leading to potentially catastrophic disruptions, especially in critical industries.

- Over-Specialization & Limited Flexibility: Dark factories are better suited to standardized, repetitive tasks. However, they struggle with flexibility and may not be able to adapt quickly to changes in market demands or product types, limiting their scalability in certain sectors.

Where Do Humans Fit In?

Even in a largely automated world, humans are still needed, but their roles are changing. Instead of managing individual tasks, humans will serve as “enhanced operators”—individuals with a broad understanding of factory systems, trained to intervene when needed. While the headcount may decrease, collaboration between humans, robots, and AI will still be essential to tackle complex tasks.

This shift also means that industries must invest in new training programs and rethink their workforce structure. Human oversight will remain necessary for strategic decision-making and problem-solving in areas where automation may not yet fully deliver.

How to Move Forward: A Strategic Approach

Successfully transitioning to a dark factory model requires careful planning:

- Transformation Roadmap: Companies should map out a clear vision of their automated future, identifying which processes are suitable for automation and understanding the full scope of required investment. A phased approach, like implementing a “dark shift” overnight, can help test the concept before fully committing.

- Cybersecurity First: Given the increasing connectivity of dark factories, robust cybersecurity measures must be integrated into the design from the start, not as an afterthought.

- Human Impact Consideration: Companies must address workforce transformation. Retraining programs should be part of the broader strategy to ensure the human element remains relevant in an automated environment.

- Scalability and Flexibility: Successful dark factories must remain adaptable to changing market conditions. Detailed monitoring and continuous optimization will be key to scaling operations efficiently.

The Road Ahead: Challenges and Triumphs

The rise of dark factories represents a transformative shift, offering many potential benefits such as cost efficiency, sustainability, and improved safety. However, the journey will not be without its difficulties. As seen in the history of automation, even the most advanced systems have struggled to meet market demands. Examples like IBM’s 1980s failed factory, or Tesla’s scaled-back automation in its Fremont facility, show that flexibility remains key.

Yet, success stories do exist. FANUC, a robotics manufacturer in Japan, operates a fully automated facility where robots assemble other robots—offering a glimpse into the potential of dark factories done right.

In conclusion, dark factories offer a vision of the future that is enticing—cost-efficient, productive, and sustainable. But companies must tread carefully, weighing the potential benefits against the substantial challenges that lie ahead. With thoughtful planning, strategic investment, and careful attention to the human and technological aspects, dark factories can move from speculative fiction to industrial reality.