As automakers seek to reduce the curb weight of conventional and electric vehicles (EVs), metal chassis components have become a significant target for conversion to composites or hybrid systems. Photo Credit: Stellantis

All of the easy automotive applications were converted from glass and metal to plastics and composites long ago. What are left are primarily structural applications on the chassis with considerably higher performance requirements than interior trim and exterior body panels and various trim components.

On the other hand, kept in incumbent metallic materials, chassis components contribute significantly to conventional and electric vehicle (EV) mass and carbon footprint, and as a result, have become key targets for the conversion to composites and hybrid systems that combine multiple materials — often metal and composites or several types of composites — as the five applications that follow will demonstrate.

In each case, the shift from metals to composites or hybrid composite components met or exceeded benchmark mechanical performance while reducing mass and tooling costs, eliminating corrosion concerns and quite often improving noise/vibration/harshness (NVH). And all of these applications are used on high-volume vehicle platforms where affordability is a significant contributor to success.

Off-road stability

To address the needs of off-road customers, especially those driving in the desert, Ford and its suppliers developed a composite C-brace to connect left and right D-pillars to the rear roof cross-member. The Class A visible part increases rear torsional rigidity and vehicle handling while reducing mass significantly versus benchmark aluminum and steel. Photo Credit: Ford Motor Co.

An interesting and visible composite application for off-road enthusiasts can be found on the 2022 Ford Bronco Raptor sport utility vehicle (SUV) from Ford Motor Co. (Dearborn, Mich., U.S.). The component, called a C-brace, is a fully functional structural brace that joins left and right D-pillars in the rear cargo area with the rear roof cross-member to increase stiffness and torsional rigidity throughout the vehicle. While “off-roading,” the brace also helps reduce vibration transfer, which, in turn, can improve handling and lower NVH.

To address the needs of off-road customers, particularly those driving in the desert, Ford engineering set a goal of increasing vehicle torsional stiffness by 40% to improve vehicle handling and NVH characteristics. When customers had top and side/door panels off, the brace would be highly visible in the open cockpit, so maintaining Class A aesthetics — especially under long-term heat and UV exposure — were important.

Additional specifications were that the brace needed to meet all rear visibility requirements and not block the driver’s view, it had to allow the front passenger doors to be stowed securely and compactly in the cargo area without damage and it had to achieve a spring constant/rotational stiffness value of 550 kilonewton-meters per radian in the lightest possible package, especially given the weight-sensitive roof location that could shift the vehicle’s center of gravity up or down.

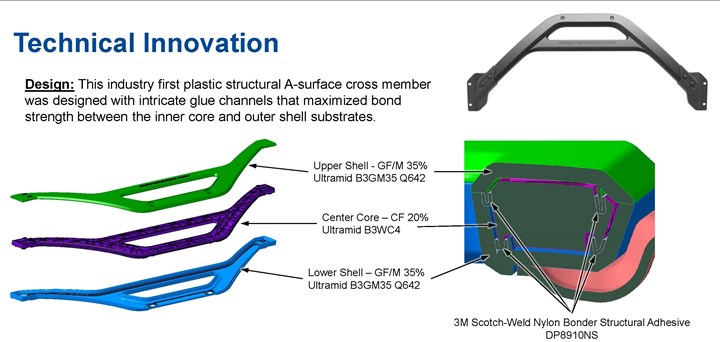

A team comprised of Ford, Tier 1 integrator/molder Montaplast of North America Inc. (Frankfort, Ky., U.S.), materials suppliers BASF Corp. (Florham Park, N.J., U.S.) and 3M Co. (Maplewood, Minn., U.S.) and toolmaker Commercial Tool Group (Comstock Park, Mich., U.S.) collaborated to design the Class A all-composite brace.

Extensive non-linear structural analysis was conducted throughout the development phase to optimize styling and appearance and to verify structural performance would meet desert durability, load displacement and stress requirements at varying temperature, roof load and torsional stiffness values, as well as to develop bonding options.

Intricate tongue-and-groove-like glue channels were molded into both the shells and the core to maximize bond strength between core and skins. Montaplast also designed and built a robotic, temperature-controlled adhesive dispensing system to meet assembly requirements, including precision glue path, bead profile, flow rate and mix ratio. To meet Ford’s harmonized color requirements for a Class A exterior surface, the outer shells are painted black. Photo Credit: Ford Motor Co.

Initially, a two-piece design was developed, which evolved into a three-piece design that was further refined into what the team called an advanced three-piece design. The latter is a sandwich with a core injection molded from 20% short carbon fiber-reinforced polyamide 6 (CF/PA6) — Ultramid B3WC4 — and skins/outer shells injection molded from 35% short fiberglass-reinforced PA6 (GR/PA6) — Ultramid B3GM35 Q642. The polymer system was specifically selected to meet Ford’s off-road desert durability requirements. A newly formulated methacrylate adhesive (3M DB8910NS) that is said to be fast curing, flexible and heat stable is used to bond all three parts together.

The final brace features several design-for-assembly features, including self-centering polyvinyl chloride (PVC) foam, sliding L-brackets in stamped steel and slotted die-cast aluminum brackets to accommodate body tolerance variations and assure fit to the body rails. Photo Credit: SPE Automotive Div.

The final composite C-brace contributes to the vehicle’s 40% torsional stiffness increase while reducing mass 55% versus aluminum and 85% versus steel options. The combination of higher torsional stiffness and lighter weight high on the vehicle body led to a lower center of gravity versus traditional materials.

Top down

Among the many accessories that can be ordered for the GMC Hummer EV pickups are either a pair of front clear or tinted Infinity glass panels, a single rear Infinity panel or a front foldable Sky Convertible Top. Photo Credit: General Motors Co.

Another interesting roof-mounted application is the frame of the Sky Convertible Top option for 2023 GMC Hummer EV pickups from General Motors Co. (Detroit, Mich., U.S.). This lightweight, manually folding soft top over the front seats helps customers create an open-air experience without the need to exit the vehicle to remove and stow glass Infinity panels that also are available for the vehicle, or to fold back and secure other types of soft tops.

When vehicle occupants desire sunshine and fresh air, they can manually fold back the soft top roof panel and stow it over the center roof panel (left), then close it again (right) to create a weathertight covering without leaving the vehicle. Photo Credit: General Motors Co.

The majority of the previous all-aluminum frame for the soft top panel was converted to glass/mineral-reinforced PA6 with recycled polymer, reducing mass at the roofline by 1.8 kilograms while still creating a weathertight seal. Photo Credit: General Motors Co.

As designed for the Hummer EV, the lightweight unit mixes metal and composite elements and provides water sealing and all-weather performance — features said to be uncommon with passenger vehicle soft tops — all while maintaining occupant safety.

GM engineering worked closely with Tier 1 Bestop Inc. (Louisville, Colo., U.S.) and materials supplier PRET Advanced Materials (Johnsonville, S.C., U.S.) to develop the folding soft top as an option for the pickup. This design replaced an all-aluminum frame with a hybrid frame of aluminum and composite, including left- and right-side door rails as well as the rear halo panel — all with molded-in color (MIC) finish — and reduced mass by 1.8 kilograms, which helped improve vehicle dynamics, including acceleration, braking and cornering.

PRET compounded a 25% short glass/15% mineral-reinforced PA6 grade (Wellamid MRGF25/15 42H-WBK). Compared to an all-fiberglass-reinforced grade, the combination of glass/mineral reinforcement is said to provide higher heat resistance, improved mechanicals, reduced warpage and good weatherability. The grade also provides excellent surface finish, which was able to meet GM’s aesthetic requirements without paint. The compound also contains post-industrial and post-consumer recycled (PIR, PCR) resin, helping reduce the manufacturing carbon footprint.

Tough structures for demanding applications

The first vehicle to sport a new composite engine stabilizer bracket is the 2022 Jeep Grand Wagoneer SUV. Not only does the composite bracket facilitate engine insertion on the assembly line but it also reduces mass by 30% and improves NVH performance. Photo Credit: Stellantis

Three interesting and different uses of similar hybrid composite technology — which can involve combinations of metal, continuous and/or discontinuous fiber-reinforced composites, and a foaming (expanding) structural epoxy adhesive/sealant — are being used in chassis components on three vehicles to replace all-metal structures at less weight, lower tooling costs and reductions in NVH. The technology was developed by Tier 1 L&L Products Inc. (Romeo, Mich., U.S.), which has a long history as an automotive supplier of adhesive/sealants, acoustical countermeasures and reinforcement technologies that improve body-in-white (BIW) crash performance and occupant comfort and safety.

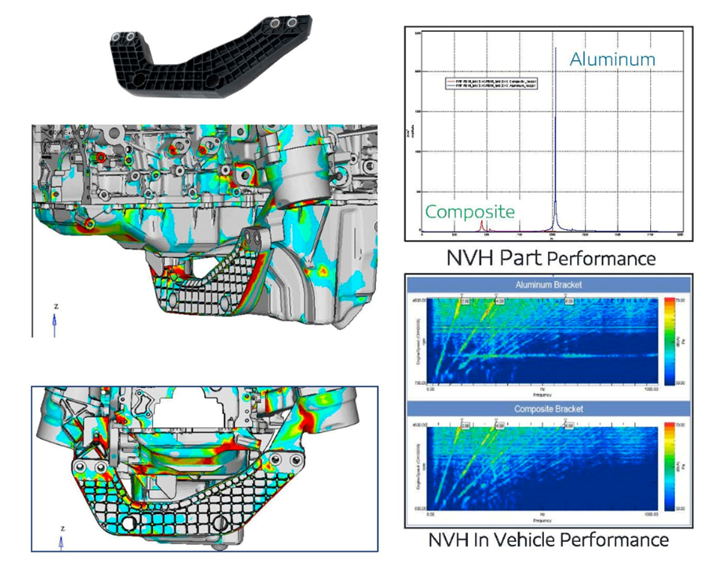

The first application is a composite engine stabilizer bracket (CESB) on 2022 Jeep Grand Wagoneer SUVs from Stellantis (Auburn Hills, Mich., U.S.). The bracket, which is positioned between left-hand and right-hand engine mounts, is designed to assist with assembly and improve NVH.

The incumbent bracket was a ribbed structure produced in die-cast aluminum, which required flash removal and secondary machining after casting. Stellantis engineering had already had positive experiences converting other mounts and brackets from metal to composite, including a running change made on rear differential mounts for the 2020 Jeep Cherokee SUV. In that case, die-cast aluminum was converted to 50% short glass/PA6/6 (Ultramid A3WG10CR from BASF), which offered a similar strength-to-weight ratio but reduced mass by 30%, lowered piece costs and improved NVH thanks to the 10-times-higher vibration damping of the composite versus metal. In that instance, the engineering team reportedly also saw the benefits of BASF’s proprietary Ultrasim anisotropic modeling software for designing composite components. They noted that changing from metal to composites for engine and powertrain mounts does necessitate taking a slightly different design approach. Rather than focusing on just stiffness based on first-mode targets, analysts need to consider the dynamic performance of the system.

The composite engine stabilizer bracket is designed to help improve engine mount stability (lateral rotational stiffness) and reduce transmission of vibrations via damping. Photo Credit: Stellantis

For the new CESB project, Stellantis once again teamed up with BASF as well as L&L Products to develop the application. In this case, a different polymer system was used. Instead of GR/PA6/6, the team switched to a fiberglass-reinforced thermoplastic polyester blend for several reasons.

First, at the time the bracket was designed, there was a global shortage of PA6/6 owing to shortages of adiponitrile (ADN), the key raw material used to produce hexamethylene diamine, one of two monomers used in the production of PA6/6. (During the same period, raw material costs for aluminum also spiked owing to trade tariffs imposed on imported metals.) Second, switching to a copolymer system involving polybutylene terephthalate (PBT) and polyethylene terephthalate (PET) meant that the resulting polymer blend has two glass transition temperature (Tg) values instead of just one, which expands the temperature range where peak loss factor — a measure of NVH damping — occurs. Depending on fiber orientation, chemistry and temperature, thermoplastics such as polyamide and polyester typically exhibit 10-20 times higher loss factors than aluminum. Using the PET/PBT blend improved NVH across the full operating temperature range of the vehicle, with peak damping between 55 and 80°C. Third, this particular composite provides very high (>20 gigapascals) modulus thanks to high glass loading plus excellent dimensional stability regardless of humidity level (since PBT and PET are far less hygroscopic than PA grades).

Stellantis reports the CESB is the first injection molded bracket that has been used to deck the engine mounts to the body and also reinforce them. It’s also said to be a new use for thermoplastic polyesters. Photo Credit: SPE Automotive Div.

The final design features a heavily ribbed, injection-molded structure of 55% short glass/PBT-PET (Ultradur B4040 G11 from BASF) plus insert-molded metallic compression limiters. Owing to the greater design freedom offered by injection molding versus die-casting, a new rib pattern was developed based on CAE simulation of the anisotropic material. This, in combination with reduced draft on the tool, permitted a tighter rib density while reducing material use versus the die-cast aluminum benchmark. Wallstock was cored out at the attachment points, eliminating the need for post-mold drilling. In fact, the composite part is ready to use right out of the mold with no secondary machining or other operations required, unlike the earlier metal bracket.

The composite bracket also provides comparable or better performance than aluminum at 30% lower mass and 7.5% lower cost, better NVH and tool life that lasts, on average, four times longer (injection mold versus casting die). Last, but certainly not least, by joining the two engine mounts with the CESB and carrying the assembly into the assembly line via the CESB, the entire assembly can be mounted to the vehicle frame prior to engine installation, making that operation easier for line workers.

An innovative hybrid composite tunnel reinforcement bracket debuted on the standard wheelbase 2021 Jeep Grand Cherokee as well as the wider wheelbase Jeep Grand Cherokee L SUVs. The bracket is important for transferring loads from the outer rails to the transmission mounts for improved crash protection as verified by the Insurance Institute for Highway Safety (IIHS) frontal small overlap test and the National Highway Traffic Safety Administration’s (NHTSA’s) New Car Assessment Program (NCAP) side impact rigid pole test. Photo Credit: Stellantis

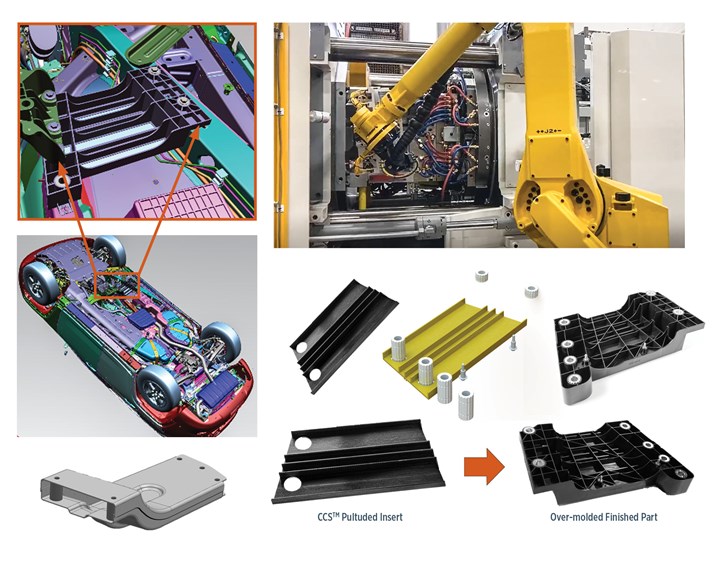

Another interesting composite chassis application — this time a composite tunnel reinforcement positioned above the exhaust system on 2021 Jeep Grand Cherokee and Grand Cherokee L SUVs — features a pultruded 80% fiber weight fraction (FWF) continuous fiberglass-reinforced polyurethane (PUR) structure (Elastocoat 74850 from BASF) that is subsequently robotically cut to size and then injection overmolded (along with six aluminum compression limiters and two steel studs) with impact-modified neat (unreinforced) PA6 (Ultramid 8350 HS from BASF).

The materials are brought together in a rotary injection press with three robots, multiple scanning stations and a laser engraving station. The process creates a lightweight, corrosion-resistant, multi-material 3D part that can carry very high axial loads (>70 kilonewtons) yet is easier to assemble and is less costly in terms of piece price and tooling investment than the steel benchmark.

L&L Products developed the pultruded insert using a new resin system from BASF that — when coupled with continuous fiberglass — has a strength-to-weight ratio three to four times higher than either steel or aluminum. Reportedly, the pultrusion process was enhanced by L&L’s process/equipment improvements and BASF’s new resin system, which permits two to three times higher throughput than the industry standard pultrusion rate of 457-610 millimeters/minute.

Location of the tunnel reinforcement bracket is shown in the top and middle left. Top right shows a robot loading the rotary press with components prior to joining the pultruded structure and the compression limiters and studs with overmolded impact-modified PA6 (right middle). Along the bottom, the benchmark-stamped and MIG-welded UHSS benchmark is shown (bottom left), along with the pultruded insert (bottom middle) and the final hybrid composite part (bottom right). Photo Credit: Stellantis

A number of assembly features were designed in to facilitate assembly for line workers, including heel-toe for two-way locating; snap features for four-way locating; compression limiters for bolted joint torque retention; and plastic-cutting threaded studs for heat-shield attachment. Furthermore, component mass was reduced 40% and subsystem mass by another 20% (total weight savings was 2.09 kilograms) versus the original multipiece, stamped and MIG-welded clamshell bracket of ultrahigh-strength steel (UHSS). And it did all of this while meeting or exceeding all functional requirements. The resulting hybrid composite structure is said to represent a completely new design for a composite tunnel reinforcement and provides an improved load path from rail to transmission support brackets.

The final hybrid tunnel reinforcement bracket is said to exceed the axial load-carrying performance of the benchmark UHSS part by 20%. The application also used a new PUR thermoset material and a new method for bonding thermoset and thermoplastic materials with integral hardware. Additionally, owing to the design freedom of injection molding, assembly aids were incorporated in the overmolded structure that made vehicle assembly easier for the operator. Photo Credit: SPE Automotive Div.

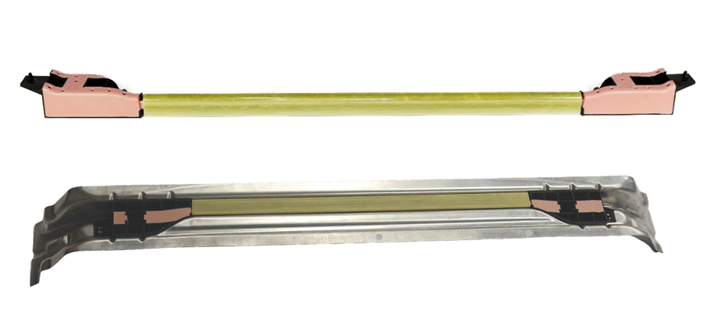

Still another innovative composite chassis application is a structural cross-member. On conventional Ford F-150 pickups, an aluminum cross-car beam — which is mounted in the transverse direction under passenger seats spanning the distance between driver-side and passenger-side doors — provides occupant protection in the event of a side-impact crash by resisting the tendency of the vehicle to buckle around the area of impact. For the all-electric F-150 Lightning model, the position of the battery enclosure and packs encroached into the space where the aluminum cross-member normally is packaged.

The all-electric Ford F-150 Lightning pickups (above) feature a hybrid composite cross-member that protects occupants as well as the battery pack and is lighter than UHSS steel or aluminum cross-members. Photo Credit: Ford Motor Co.

Developed by L&L Products using BASF materials and its own foaming adhesive/sealant, the hybrid composite cross-member features a pultruded continuous fiberglass-reinforced PUR beam (gold color) with endcaps injection overmolded with short glass/PA6 and structural foaming epoxy adhesive/sealant (pink color). This hybrid structure is, in turn, slipped into an aluminum stamping (bottom, silver) and assembled to the BIW before e-coat. Photo Credit: BASF Corp.

To protect occupants and the battery packs, Ford engineering teamed with L&L Products and BASF to develop a hybrid composite system. It begins with a hollow pultruded beam produced by L&L in 67% FVF/80% FWF continuous fiberglass-reinforced Elastocoat 74850 PUR from BASF. The beam is cut to size and L&L’s Composite Body Solution (CBS) components — consisting of a 35% GR/PA6 injection-molded carrier (Ultramid B3WG7 from BASF) overmolded with L&L’s heat-activated structural adhesive (L-5905) — are inserted into each end of the pultruded beam to serve as endcaps. This hybrid assembly is then placed inside an aluminum stamping, which is subsequently installed on the underside of the BIW. Heat produced by the e-coat drying/curing process causes the foaming adhesive/sealant to expand, bonding the composite endcaps to the composite beam, the composite structure to the metal cross-member, and locking the entire structure to the floor of the vehicle.

Although this structure is presently only used on the F-150 Lightning model, the pultruded beam was designed to fit into a smaller cross-section of the EV’s aluminum cross-car beam compared with conventional F-150s. Hence, the composite solution enabled the F-150 Lightning body structure to carry over the same mating components of the aluminum cross-car beam stack-ups from the diesel-model pickup floor, thus saving Ford from having to make additional capital investments or changes in the assembly process. Thanks to its high stiffness/weight ratio, the hybrid structure is lighter and stronger than the original aluminum cross-member and protects occupants and battery packs during severe crashes at a competitive value proposition versus other UHSS or aluminum solutions.

As these and a growing list of other applications demonstrate, composite materials — alone or in combination with other materials — are providing a slew of benefits not just to automakers and their part suppliers, but to consumers and the planet as well. With pressure to reduce mass growing ever stronger for all categories of passenger vehicles during the industry’s move to electrification, expect to see composites show up in even more diverse applications on cars and light trucks.

Landscape Photo Credit: General Motors Co.